Anchor and hold water delivery evolutions for structure fires in the wildland-urban interface

By Paul Shapiro | FireRescue Magazine Volume 12, Issue 12

The following information is quoted from FIRESCOPE, which is an organization the state of California put together to have plans in place for major disasters—wildland fires being one of them. To give you a better idea of what anchor and hold is all about, I have quoted the definition given by FIRESCOPE.

Anchor and Hold

Anchor and hold is a tactic using control lines and large water streams from fixed water supplies in an attempt to stop fire spread. The goal is to extinguish structure fires, defend exposures, and reduce ember production.

• Anchor and hold can be referred to as taking a stand to stop the progression of the fire.

• Anchor and hold tactics are more effective in urban neighborhoods where the fire is spreading from house to house.

• Establishing an anchor and hold line requires considerable planning and effort and uses both fixed and mobile resources.

– Fixed engines should be spotted in safe areas where they can safely withstand any fire situation.

– Mobile engines or task forces can engage in individual structure defense actions or perimeter control and resupply from fixed water sources.

– Mobile engines should be prepared to redeploy to other areas should the fire escape the anchor and hold line.

• Ground resources, such as engine crews and hand crews, should staff hoselines and be prepared to extinguish hot spots, fire perimeter, and structures.

– Hand crew Strike Teams should be deployed to construct fire control lines wherever needed and conduct firing operations.

Five Factors

The anchor and hold strategies presented in this section are based on the five following factors:

1. Can it be done safely?

2. Is there an adequate water supply?

3. Is there adequate staffing?

4. Is there adequate equipment?

5. Is there a will to get the job done?

Tactics

The anchor and hold tactics involve fire suppression units connecting to a hydrant to maintain an uninterrupted water supply to hopefully allow for higher flowing fire streams.

I was inspired to write this section by Battalion Chief (Ret.) Mike Alder from the San Bernardino City (CA) Fire Department. In a previous year, the city had a devastating wildland fire called the Panorama Fire that burned hundreds of homes. Alder saw a need for a change in tactics to help prevent this from happening again. He, along with his department members, developed the anchor and hold tactics. These tactics were proven to be very effective in the 2003 Old Fire that hit the city, as members claim they saved hundreds of structures. In doing my research, I met the chief and got permission from him to seek improved water delivery capabilities for anchor and hold tactics.

The anchor and hold tactics covered in this text were developed using three phases of operations, keeping safety and maximum efficiency as the goals. They include the following:

1. Maximizing the water supply.

2. Stream performance.

3. Knockdown capabilities.

Fire Attack

The basic firefighting strategy for anchor and hold operations is to establish a water supply and initiate an attack on the fire to achieve a quick knockdown on the involved structures to stop or slow down the threat of fire spread to exposures. The safest and most efficient way to do this is with a blitz attack operation. A blitz attack involves hitting a body of fire with an overwhelming amount of water to achieve a knockdown as quickly as possible.

Based on the blitz attack concept, as well as the type of tactics involved with fighting these fires, for the most part fire streams will be directed from the outside with the goal of getting quick knockdowns. Simply stated, the higher the flow, the quicker the knockdown.

A quick attack pickup truck flowing 1,455 gpm at 150 nozzle pressure. (Photo by author.)

The unit at the hydrant should make its hookup with at least two LDH soft suctions. (Photo by author.)

There are two weapons of choice for this operation when it comes to the attack unit. One is a standard engine company with at least a three-inch deck gun, which is the most common. Keep in mind that this gun can be replaced with a 2,000-gallon-per-minute (gpm) gun fairly easily and at a low cost, which will allow for potential higher flows if available but more importantly higher nozzle pressures because of the gun being able to handle a 1,010-pound nozzle reaction vs. a 631-pound nozzle reaction with the standard 1,250-gpm gun. These high-pressure streams (150 psi works best) work well in producing better penetration as well as being able to perform better in wind, which is almost always present at wildland fires.

The second weapon for this operation is a four- inch master stream mounted to a full-size pickup truck with stacked tips ranging from 13⁄8 inch to two inch, producing flows from 866 gpm to 1,455 gpm with a 150-psi nozzle pressure.

The handlines are designed for large flow and lighter in weight using two-inch hose with 2½-inch couplings. The flows from the two-inch handlines range from 250 gpm to 325 gpm. Again, this is based on the ease of deployment because of the weight of the hose when charged and the tactics the handlines will be used with.

Water Supply

An engine company will always be placed at the hydrant if it is in service and capable of the required flows. The engine will be set up in a relay to the attack unit. The reason for the relay is to maximize the hydrant pressure and flow. Before deploying the pumping apparatus and the supporting hose evolutions, it is helpful to know how much water is available for the operation.

Hydrant use requires a method for evaluating available water. Remember, we are trying to support master streams. The easiest way to determine an approximate hydrant flow capability is to connect the engine to the hydrant based on a high-volume hookup. Then, simply fire up the deck gun and take a reading with a handheld pitot gauge using a flow chart to reference the flow. A hydrant worth using should hopefully have at least 1,000 gpm. If, on the other hand, you are only able to get 500 gpm or less, this operation will be questionable as to whether the operation will work from this hydrant. The choice would be yours.

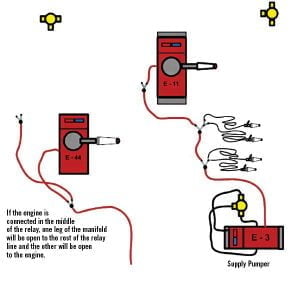

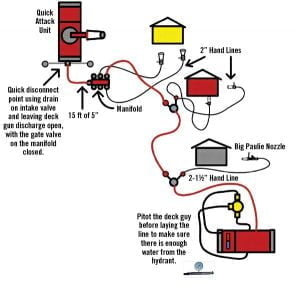

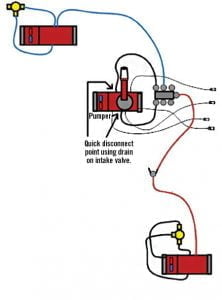

There are various strategies for flowing water from the hydrant. (Images by author.)

Water Supply Hose Evolution With a Pumper or Quick Attack Unit

In the early days, a common hose evolution used in anchor and hold tactics involved a small-diameter hose supply line connected directly from the hydrant to support pumpers attacking the fire. This concept dramatically decreases the flow from the hydrant because of the higher friction loss in the 2½-inch or three-inch supply lines as well as the low fixed system pressure available from the hydrant.

The new evolutions described in this section are based on using only two units per evolution. This is done for a couple of reasons. Because we are trying to achieve a big knockdown on a structure, we are looking to get at least a 1,000-gpm stream and, hopefully, higher. A single hydrant in a residential area will most likely not have much more than that, so using multiple pumpers at the same time will interfere with the 1,000-gpm stream goal. The other reason is that traditionally on wildland fires, units are scarce, so multiple units on a single evolution may not be possible.

I recommend using five-inch large-diameter hose (LDH) attack hose for the operation because it has a higher operating pressure, which is 275 psi, vs. the LDH supply hose that can only be used up to 185 psi. The higher-pressure hose will allow the following operations to be conducted with better results:

• High-pressure smooth bore tip operations at a maximum of 150 psi nozzle pressure (NP). This increases penetration and helps battle the stream destroying wind.

• Longer supply lines because of less friction loss. Basically, a five-inch line can move twice as much water as a four-inch line if the water volume is available from the hydrant.

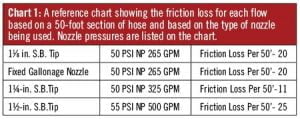

Chart 1: A reference chart showing the friction loss for each flow based on a 50-foot section of hose and based on the type of nozzle being used. Nozzle pressures are listed on the chart.

The most efficient method for moving the required flow through the hose evolution, as mentioned earlier, is to place a pumper at the hydrant in a relay pump operation to discharge the water under higher pressure to the receiving unit. The unit at the hydrant should make its hookup with at least two LDH soft suctions. The attack unit, whether it is another engine or the quick attack unit such as the one featured in this section, will then lay a single line down the street that the fires are on. If multiple targets are going to be covered by the evolutions, large jumbo gated wyes should be placed in the evolution at specified locations to allow the single pumper to connect to different locations as needed without shutting the operation down.

Hookup Big

The method for using the quick attack unit involves only one quick attack unit plus the engine at the hydrant. When the relay line is laid, again a jumbo gated wye can be put in line where a fire attack is needed and left open on the relay discharge port to provide the water to the entire relay evolution. Several jumbo gated wyes can be placed inline where needed, again left open for the relay. The quick attack unit can start to go to work at any of the wyes based on the needs of the situation. When a knockdown is achieved, the crew simply closes the gate on the wye supplying the quick attack unit and goes to the next one and makes the hookup again. If needed, a smaller gated wye can be connected to any of the jumbo wyes that are not in use by the quick attack unit for small handlines.

It’s a known fact that the fireground area in the wildland interface and conflagration can be very dangerous, thus requiring the rapid exit of the area to maintain safety. Because supply lines are being used in anchor and hold operations, a quick disconnect is crucial. The quickest way to do this is to have the jumbo gate valve or large manifold within the supply line evolution close to the pumper. Connect a short section of LDH, about 15 feet, between the gate valve and the pumper intake. When the valve is shut down the drain valve on the wye drains the excess pressure from the intake valve in seconds.

Handlines

The handlines in an anchor and hold operation are designed for two different target flows. I say target because it could be difficult to dial in the exact gpm. You want to be able to flow a big water line for the areas that the deck gun can’t reach. A flow of 265 gpm is suggested and possible. To make this operation as simple as possible one size handline is used to obtain all flows; it is two-inch hose with 2½-inch couplings. This hose is just a couple of pounds heavier than 1¾ inch and the maneuverability of it is not much of an issue because the lines will more than likely not go interior. These lines are connected to any of the manifolds in the evolution or to the attack pumper if used. Dialing in the correct discharge pressure is done at the manifold or the pumper if used. A simple reference chart should be designed to show the friction loss for each flow based on a 50-foot section of hose and based on the type of nozzle being used; the nozzle pressure should also be added.

A 2½-inch × 2½-inch gated wye with gauge mounted on the jumbo wye itself as well as connected to the outlet before the hose. (Photo by author.)

Since it will not be possible to set the discharge pressure for the handline from the manifold by the pumper, it has to be done at the manifold itself. An inline gauge should be placed between the discharge port of the manifold and the handle and the pressure should be set while the line is flowing.

Fixed Master Stream

The main purpose of the master stream is to knock the fire out of the burning structure quickly. Water priority should be given to the master stream. When effective, the master stream can achieve a knockdown in a minute or less. High-pressure smooth bore tip operations are encouraged for deep penetration and battling wind conditions. Effective flow range should be between 500 and 1,000 gpm. If the master stream appliance being used is a 2,000 gpm or higher and the water is available, a 1,456-gpm flow at 150 nozzle pressure can be produced safely.

It’s important to make sure all units are on the same page as far as what evolution is to be used. A water management officer should be used. The person filling this position should be familiar with the evolutions discussed, available water supply, units involved, and available staffing.

Paul Shapiro is a 36-year veteran of the fire service and a retired engineer from the Las Vegas (NV) Fire Department. He is director of Fire Flow Technology and a national instructor on large-flow water delivery. Shapiro has authored numerous articles for fire trade magazines and a video on large-flow water delivery.

Paul Shapiro is a 36-year veteran of the fire service and a retired engineer from the Las Vegas (NV) Fire Department. He is director of Fire Flow Technology and a national instructor on large-flow water delivery. Shapiro has authored numerous articles for fire trade magazines and a video on large-flow water delivery.